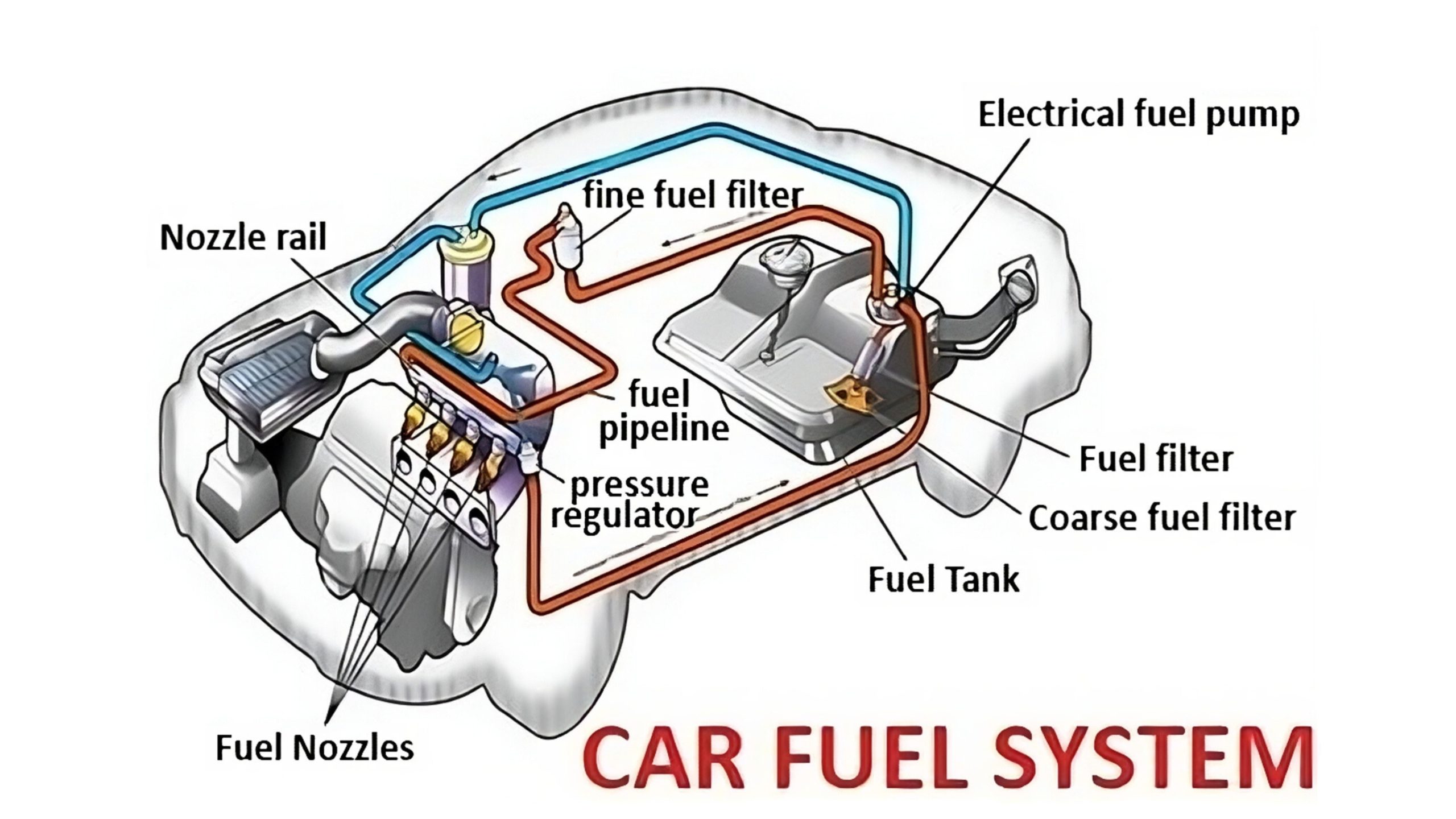

Your vehicle’s fuel system can be likened to the human vascular system, where various organs of the body, like the veins, arteries, and the heart, take part in blood circulation, fuel circulation in your vehicle goes through different processes and involves certain vehicle components. The purpose of your vehicle’s fuel system is to store and supply the gasoline or diesel fuel your engine needs to run, the fuel pump acts like the heart, the fuel lines act like the veins, while the fuel filter acts like the kidneys. A failure in any of these key fuel system components would result in the same devastating effects to your vehicle as a failure in any of the human vascular components would to your body.

Basic Fuel Components

The various fuel system components that are pivotal to seamless circulation of fuel in a vehicle include, the fuel pump, fuel gauge, fuel tank, fuel filter, fuel lines, and fuel injectors.

Fuel Pumps

A fuel pump is a part of an automobile that supplies fuel from a fuel container to the carburetor of an IC engine. A fuel pump is an important part of the IC (Internal Combustion) engine. This is because the fuel supply is important to keep the engine running.

Fuel pumps can be located inside the fuel tank (electric fuel pumps) or outside the tanks (mechanical fuel pumps). The electric fuel pumps generate a constant flow of fuel to the engine, and fuel not used is returned to the tank, this helps to reduce the chance of fuel getting too hot since it is never kept close to the hot engine for very long. Electric fuel pumps greatly reduce the risk of fire, they can spark and ignite fuel vapors, but liquid fuel will not explode. For this reason, positioning the fuel pump inside the tank, submerged in fuel, is the best placement for the fuel pump. Submerging the fuel pump in the cool fuel also helps prevent it from overheating.

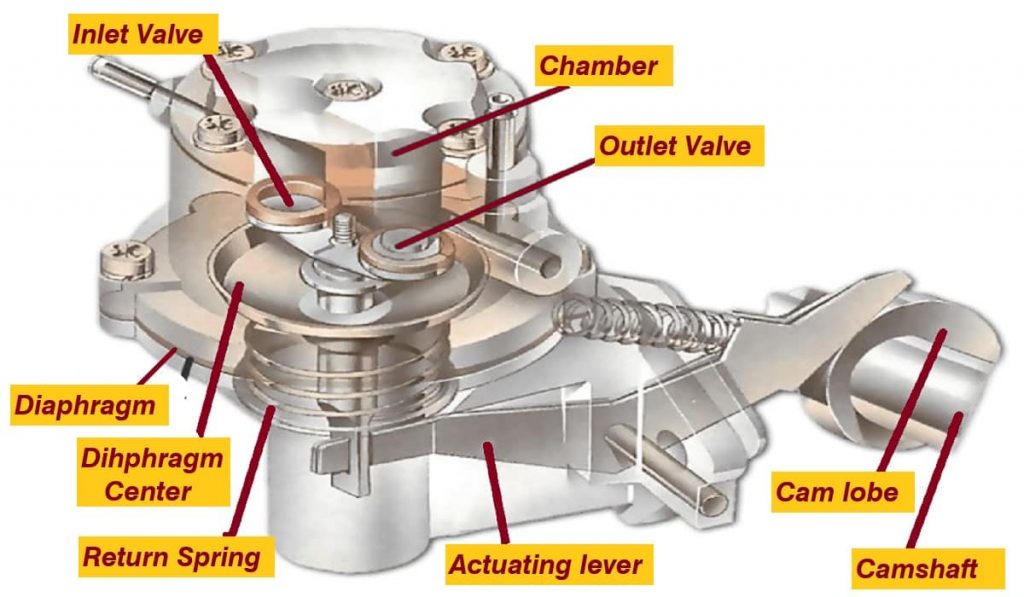

Mechanical fuel pumps, on the other hand was very common before the general acceptance of electronic fuel injection, maximum automotive gasoline engines used mechanical fuel pumps to move fuel from the fuel container to the carburetor bowl. The mechanical fuel pumps are driven by the eccentricity of the engine’s camshaft. It is usually located beside the in-line cylinder block engine. According to an article on Mechanicalboost.com, “A mechanical fuel pump drives through a camshaft or a special shaft that drives by a crankshaft. When the shaft rotates, the cam goes under the pivot level and pushes the shaft up at one end.

“The lever’s other end loosely connects to the rubber diaphragm that forms the bottom of the chamber floor of the pump, moves downward, and is used to pull the diaphragm.

“As the lever forces the diaphragm downward, a suction force is created that pulls fuel inside the pump by a check valve along the fuel pipeline. When the rotating cam continues to rotate and no longer pushes the lever, the return spring moves the lever back and releases its tension on the diaphragm.

“The loosely connected lever doesn’t force the diaphragm upward, but the return spring pushes against it. This diaphragm or membrane can only be moved upwards by draining gasoline from the engine’s chamber. Gasoline cannot be returned from the 1st check valve, so it drains into the carburetor through another valve. The carburetor draws gasoline from the float chamber needle valve only when needed.”

The Fuel Tank

The fuel tank is a reservoir designed to safely store fuel. While filling the fuel tank, fuel travels through a filler tube into the tank, which is usually sealed with a fuel cap. Inside the fuel tank, there is a sending unit which tells the fuel gauge how much fuel is in the tank, thereby ensuring that you know when your vehicle is low on fuel.

However, Modern fuel tanks are more complex, they contain emissions control components to prevent fuel vapors from evaporating into the atmosphere. The fuel pump creates positive pressure and draws fuel from the tank, it then pushes fuel through the fuel lines and fuel filter, delivering it to the fuel injectors at the engine. The fuel is then delivered to the cylinder combustion chambers and ignited. When your fuel system accomplishes this process, your engine can run. Pressurized and filtered fuel flows through the fuel lines to the engine and reaches the fuel injectors.

However, Modern fuel systems are complex and ultimately controlled by the vehicle’s computer, which has helped vehicles reach amazing levels of fuel economy, reduced emissions, and increased engine performance. The systems are relatively maintenance free, but there are steps you can take to improve the life and performance of your fuel system.

- If your vehicle has an in-line fuel filter, make sure you replace it at the recommended interval.

- Inspect your fuel filler cap to make sure it seals properly against the filler neck.

- Get your fuel injection system cleaned every three years or 45,000 miles traveled, by a reputable automotive repair shop under the network of Fixit45 workshops.

- If you notice any symptoms such as hard starting, rough idling, hesitation, fuel leaks, fuel smells, or poor overall performance, have your vehicle’s fuel system inspected by a Fixit45 certified technician.